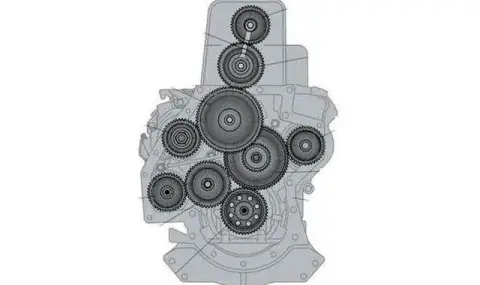

Volkswagen is working on a fundamentally new type of internal combustion engine, which is aimed at significantly reducing maintenance costs, increasing reliability and simplifying the design of the drive of auxiliary units. According to data published in leaked patent documentation, the company plans to abandon traditional timing drive mechanisms, such as a timing belt or metal chain, in favor of a system with direct gears.

This solution assumes that the camshafts and valves in the new engine will rotate thanks to a cylindrical gear, without the participation of classic wearing elements that require regular replacement or tensioning. This not only simplifies maintenance, but also eliminates the possibility of chain stretching or belt breakage - problems that often cause serious damage.

In addition, according to available information, the new engine will also lack the traditional belt drive for additional accessories such as water and oil pumps, air conditioning compressor and power steering. All of these units will operate either electrically or through the same rigidly connected gears, which will eliminate another group of wearing components.

An important point is the return to two valves per cylinder - a scheme that has practically disappeared in modern engines, where the four-valve architecture dominates. However, such a step may be logical for an engine that is not designed for sports dynamics, but for high efficiency and long service life. Volkswagen is also likely working on a hybrid powertrain in which the internal combustion engine does not take on the main load and is not directly connected to the wheels, but works exclusively as an electricity generator.

Such a system allows for reduced engine speed requirements, as it operates primarily in a fixed range optimized for fuel efficiency. In such conditions, the spur gear design, despite the potentially higher noise level, becomes more acceptable - because the frequency and nature of the engine's operation are predictable and controlled by the electronics. In addition, when used in a closed encapsulated configuration, where the motor acts only as a power source, noise and vibration can be further isolated.

This is not the first time Volkswagen has used spur gears in its engines. One example is the 2.5-liter five-cylinder diesel engine installed in the first generation of the Touareg. It uses gears to transmit torque to the camshafts, which provides higher precision and durability compared to belts or chains, albeit with some compromises in noise levels.

At this stage, Volkswagen does not disclose the technical characteristics of the new unit, in particular, it is not known whether it is a gasoline or diesel engine and how many cylinders it has. However, taking into account market trends and the concern's strategic course for electrification of the model range, it can be assumed that the new development is aimed at application in hybrid platforms, where key criteria are minimizing maintenance, reducing ownership costs and environmental efficiency. The first details about the serial implementation of this technology are expected to appear very soon.